No matter what pipe system you use underground or above ground, selecting the right coupling has never been easier. Making sure your coupling has the exact fit, no leakage as well as easy to install and fix is one of the hardest jobs for anyone.

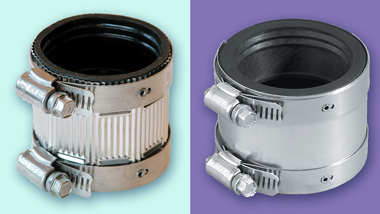

Nevertheless, choosing the wrong one can make your regret your decision as you will be needing to call the plumber more than expected. However, with the most popular and trustable couplings, no-hub and shielded, we are going to do a head-to-head comparison here.

In the No-Hub Vs Shielded Coupling, we will cover everything that matters to you, and you will be able to pick the right one for you.

Let’s start with the basics!

What Is No-Hub Coupling?

No hub coupling, as the name indicates, allows you to utilize a hubless cast iron pipe and fitting without the need for a hub or spigot. It was difficult for plumbers to join one iron pipe to another back in the day, so they used molten lead to do it.

Since these couplings are so simple to install, they are far more efficient for anybody dealing with pipes. On the other hand, Fernco has a patent on the design utilized in no-hub coupling. As a result, this particular fitting is also known as the Fernco coupling no hubs.

However, they do have various sorts of couplings that are intended for utilization in different situations. Fernco provides no-hub couplings in three different types: standard, medium, and heavy-duty. Each one has a varied torque range, ranging from 60 to 120, with the maximum being found in the Heavy Duty one.

Where Can I Use No-Hub Coupling?

Now that you know everything about these no-hub coupling, let’s take a look at where you can use them for efficient fittings.

The first thing that comes to mind is commercial space. Any business establishment, such as an office, school, or other incorporation, is required to utilize cast iron pipe for drainage, necessitating the installation of a no-hub connection. The no-hub connection can come in useful when our hands can’t reach it because of its easy installation.

Aside from drainage, the Fernco connector is designed specifically for sewage systems and may thus be utilized in any underground fitting. As a result, these underground no hub coupling are built of tough materials that can sustain pressures of up to 4.3 PSI.

However, before you consider installing these handy couplings, you need to think about the diameters of your cast iron or PVC pipes. If you’re working with smaller pipes, a 2″ no hub coupling or one that’s adequate for your pipe’s size will suffice. Nevertheless, you can’t rely on couplings as much for larger-diameter pipes as you can for smaller ones.

What Is Shielded Coupling?

Shield coupling is also used for underground sewage systems but is specifically made for withstanding high forces inside the pipe. Underground pipes are mostly made for taking out a huge chunk of liquids from one place to another. And for this, the pipes need to be able to do the transfer without any leaks or breaking.

Since the pipes are so vital to the entire area, even a minor malfunction might result in a massacre, and repairing them will be extremely difficult. As a result, the pipes must be properly fitted so that they do not burst.

Thus, the shielded coupling, which includes a heavy-duty shear ring, offers the pipes a significant amount of resistance to the high sewage flow. Resulting in a superb fit and no need for a replacement anytime soon.

Nonetheless, shielded coupling is employed to ensure that the pipes are perfectly aligned. The pipes must be straight, not even an inch up or down. As a result, the shielded connection is intended to keep the pipes aligned.

Where Can I Use Shielded Coupling?

Shielded fernco coupling is mostly used where the pipes must be able to withstand a huge chunk of pressure. Mostly, these are found in the high diameter based pipes as they are the main ones supplying the sewage all over the world.

Furthermore, they are performance enhancers. These couplings use straightly aligned pipes to ensure that sewage may flow at a continuously high pace without being stopped owing to improper placement.

However, these couplings are not limited to cast iron pipes; they may also be used with PVC and other types of pipes. A shielded coupling PVC is known for having a lower number of pipeline failures and being more efficient. As a result, it is perfectly acceptable to use these connections above ground rather than simply beneath.

No-Hub Vs Shielded Coupling: Comparison Table

To put it all down, let’s look at the head-to-head differences between the two below.

| No-Hub Coupling | Shielded Coupling |

| Requires no prior knowledge to install. | Might need some professional help to install |

| Doesn’t affect the flow at all | Enhances the flow due to its perfect alignment |

| Best for cast iron pipe only | Compatible with an iron pipe, PVC, and other pipes |

| Excellent sealing pressure and holding power | Specially designed gaskets for tight-fitting. |

| The interlocking clamp design for being leakproof | Usual clamp design but makes sure no leak is there |

What are the Differences Between No-Hub and Shielded Coupling?

The main difference between no-hub and shielded coupling is the diameter of the pipe. You can easily trust a no-hub coupling when it comes to cast iron pipes with smaller diameters. On the other hand, for a sewage line that constantly needs to supply a great amount of wastage and thus needs a larger diameter pipe, the shielded coupling is the handiest.

However, there are more differences to know for proper utilization. Let’s check them out.

Installation Difficulty

When it comes to ease of installation, no one beats the no-hub options. Anyone without any prior expertise may install it without the need of a hub or spigot. This is the sole reason most people recommend using no-hub coupling in their system. On the other hand, a shielded one would need some training before putting your hands on the pipes.

Reliable

The only reason anyone would pick shielded couplings is for their reliability. They’ve been deliberately designed to resist high pressure without bursting.

Furthermore, the gaskets are custom-made to avoid leaks and maintain the connection tight. On the other hand, the no-hub connection is only suitable for pipes with a lower diameter.

Easy To Fix

Even though shielded couplings are more dependable, no-hub couplings are the best when it comes to fixing them. There will be spots where your hand won’t be able to reach and hence suffer when it comes to underground fittings. However, the no-hub ones can reach places where the shielded ones cannot.

Conclusion

To conclude, there’s no winner here in this competition of No-Hub Vs Shielded Coupling. It completely depends on your perspective of which one will be perfect and the winner for you.

If you are thinking of somewhere where you have to transfer heavy loads, then yes, the shielded couplings are the best ones to go for. However, if you are too lazy to fix the pipeline failures and don’t like to call the plumbers every week, then the no-hub couplings are your first option to go for.

Nonetheless, the question is not which one is better, but which is better at what. Each of them excels in some areas that the other does not. So, depending on your requirements, choosing one coupling that specializes in your specific task is the best solution.